VOLUME 16 NUMBER 1 (January to June 2023)

SciEnggJ. 2023 16 (1) 001-007

available online: January 31, 2023

*Corresponding author

Email Address: jrcdizon@bpsu.edu.ph

Date received: September 11, 2022

Date revised: November 23, 2022

Date accepted: December 13, 2022

DOI: https://doi.org/10.54645/2023161ZYP-27

ARTICLE

Fabrication and Testing of a Vapor Polishing Device for ABS 3D-Printed Parts

Ciara Catherine L. Gache1, Sherwin A. Mesa1, Thea Clarice L. Prado1, Christian G. Canonoy1, Jimwell E. Pengson1, Brian J. Tuazon2,3, Michaela T. Espino1,3, Rigoberto C. Advincula4, and John Ryan C. Dizon*1,3

1Department of Industrial Engineering,

College of Engineering and Architecture,

Bataan Peninsula State University – Main Campus,

City of Balanga, Bataan, 2100, Philippines

2Department of Mechanical Engineering,

College of Engineering and Architecture,

Bataan Peninsula State University – Main Campus,

City of Balanga, Bataan, 2100, Philippines

3DR3AM Center, Bataan Peninsula State University – Main Campus,

City of Balanga, Bataan, 2100, Philippines

4Department of Chemical and Biomolecular Engineering and

Institute for Advanced Materials and Manufacturing,

University of Tennessee, Knoxville, TN 37996, USA;

Department of Macromolecular Science and Engineering,

Case Western Reserve University, Cleveland, OH 44106, USA;

Department of Materials Science and Engineering,

University of Tennessee, Knoxville, TN 37996, USA;

Center for Nanophase Materials and Sciences,

Oak Ridge National Laboratory, Oak Ridge, TN 37830, USA

College of Engineering and Architecture,

Bataan Peninsula State University – Main Campus,

City of Balanga, Bataan, 2100, Philippines

2Department of Mechanical Engineering,

College of Engineering and Architecture,

Bataan Peninsula State University – Main Campus,

City of Balanga, Bataan, 2100, Philippines

3DR3AM Center, Bataan Peninsula State University – Main Campus,

City of Balanga, Bataan, 2100, Philippines

4Department of Chemical and Biomolecular Engineering and

Institute for Advanced Materials and Manufacturing,

University of Tennessee, Knoxville, TN 37996, USA;

Department of Macromolecular Science and Engineering,

Case Western Reserve University, Cleveland, OH 44106, USA;

Department of Materials Science and Engineering,

University of Tennessee, Knoxville, TN 37996, USA;

Center for Nanophase Materials and Sciences,

Oak Ridge National Laboratory, Oak Ridge, TN 37830, USA

Post-processing plays a significant role in improving the surface and mechanical properties of 3D-printed parts. One of these post-processing methods is vapor polishing which utilizes acetone to polish 3D-printed Acrylonitrile Butadiene Styrene (ABS) specimen. This process is usually done using an improvised vapor polishing set-up to achieve the desired surface finish of parts. Hence, in order to accomplish a uniform and standard polishing procedure for laboratory use, a vapor polishing device has been developed in this study.

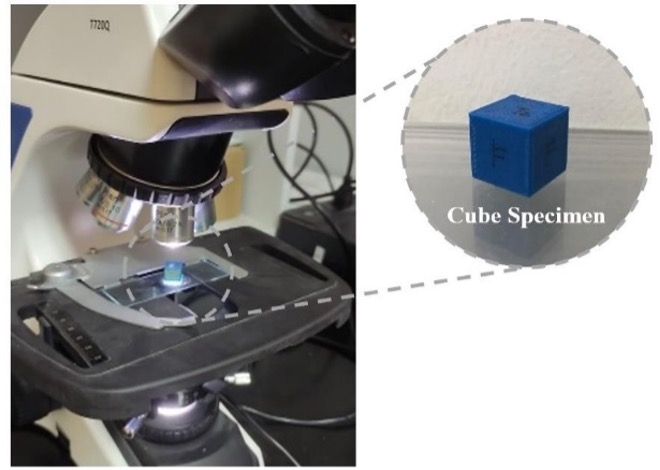

To assess the efficiency of the said device, the resulting surface roughness, dimensional accuracy, and tensile strength of ABS 3D-printed polished specimens have been evaluated and compared to unpolished specimen. The surface roughness of the cube specimen was captured using a Trinocular Microscope and was uploaded to the Mountains9 Topography software. Further, the dimensional accuracy of both polished and unpolished specimen has been measured using a digital Vernier Caliper. The data demonstrated that the polished specimen’s surface was enhanced while its shape, geometry, and dimension were preserved. Tensile tests on two (2) sample sets of polished and unpolished specimens revealed that polishing with acetone vapor using this developed device could improve the specimen’s tensile strength.

To assess the efficiency of the said device, the resulting surface roughness, dimensional accuracy, and tensile strength of ABS 3D-printed polished specimens have been evaluated and compared to unpolished specimen. The surface roughness of the cube specimen was captured using a Trinocular Microscope and was uploaded to the Mountains9 Topography software. Further, the dimensional accuracy of both polished and unpolished specimen has been measured using a digital Vernier Caliper. The data demonstrated that the polished specimen’s surface was enhanced while its shape, geometry, and dimension were preserved. Tensile tests on two (2) sample sets of polished and unpolished specimens revealed that polishing with acetone vapor using this developed device could improve the specimen’s tensile strength.

© 2024 SciEnggJ

Philippine-American Academy of Science and Engineering