VOLUME 18 NUMBER 2 (July to December 2025)

SciEnggJ. 2025 18 (2) 304-319

available online: 23 September 2025

DOI: https://doi.org/10.54645/2025182RNB-95

*Corresponding author

Email Address: mmrubio1@up.edu.ph

Date received: 02 July 2025

Dates revised: 30 July 2025 and 19 August 2025

Date accepted: 08 September 2025

ARTICLE

Atmospheric pressure plasma treatment of pure cotton textile for improved hydrophilicity and optimized dyeability via response surface methodology

the Philippines Baguio, Governor Pack Road, Baguio City,

Benguet 2600

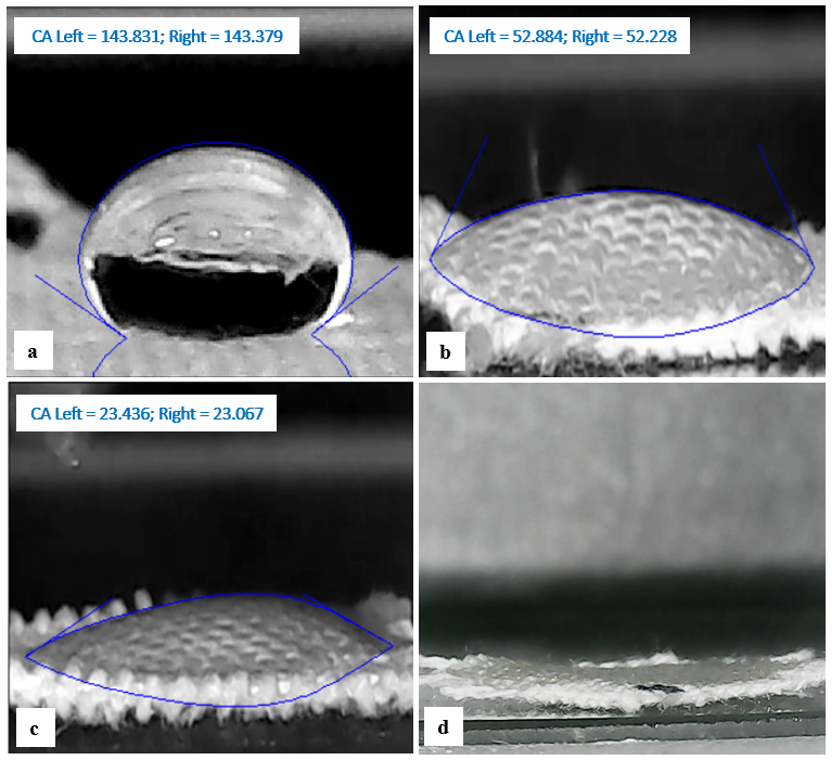

Raw cotton fibers contain non-cellulosic impurities that impart hydrophobic properties, making the dyeing process water- and energy-consuming. Conventional methods such as desizing, scouring, and bleaching involve hazardous chemicals, raising environmental concerns. In this study, the potential of atmospheric pressure plasma in surface modification to improve the hydrophilicity and dyeability of pure cotton textiles was investigated. Cotton samples were treated using an Atmospheric Pressure Plasma Jet (APPJ) system with an argon-oxygen gases mixture for 30, 60, and 90 seconds. Optical Emission Spectroscopy (OES) confirmed the presence of ionized argon and oxygen species in the plasma plume. Scanning Electron Microscope (SEM) images revealed surface etching, increased roughness, and microcrack formation after treatment. Increased absorbance of hydrophilic functional groups after plasma exposure were detected through a Fourier Transform Infrared Spectroscopy (FTIR). As plasma treatment time increased, significant improvements were observed in contact angle reduction, water absorbance time, and fabric weight indicating enhanced hydrophilicity. Moisture and dye uptake efficiencies also increased correspondingly. Optimization using the Box-Behnken Design of Response Surface Methodology identified the optimum conditions as 90 seconds of plasma exposure, 9 LPM oxygen flow, and 45 minutes dye contact time. The predicted dye uptake efficiency was 10.21%, closely aligning with the experimental value of 9.85% (3.56% relative error). Compared to untreated cotton (3.56%), plasma-treated samples achieved a 177% increase in dye uptake. These findings highlight the potential of APPJ treatment as a sustainable, energy-saving, and cost-effective approach for improving cotton textile processing.

© 2026 SciEnggJ

Philippine-American Academy of Science and Engineering