VOLUME 18 (Supplement)

SciEnggJ 18 (Supplement) 289-298

available online: 11 August 2025

DOI: https://doi.org/10.54645/202518SupPTO-29

*Corresponding author

Email Address: nandiyanto@upi.edu

Date received: 10 September 2024

Date revised: 11 November 2024

Date accepted: 30 December 2024

ARTICLE

FTIR analysis of pyrolyzed LLDPE and polystyrene microparticles and their chemical reaction mechanism completed with computational bibliometric literature review to support sustainable development goals (SDGs)

2Universitas Sultan Ageng Tirtayasa, Serang, Indonesia

3IPB University, Bogor, Indonesia

4Universiti Brunei Darussalam, Brunei Darussalam

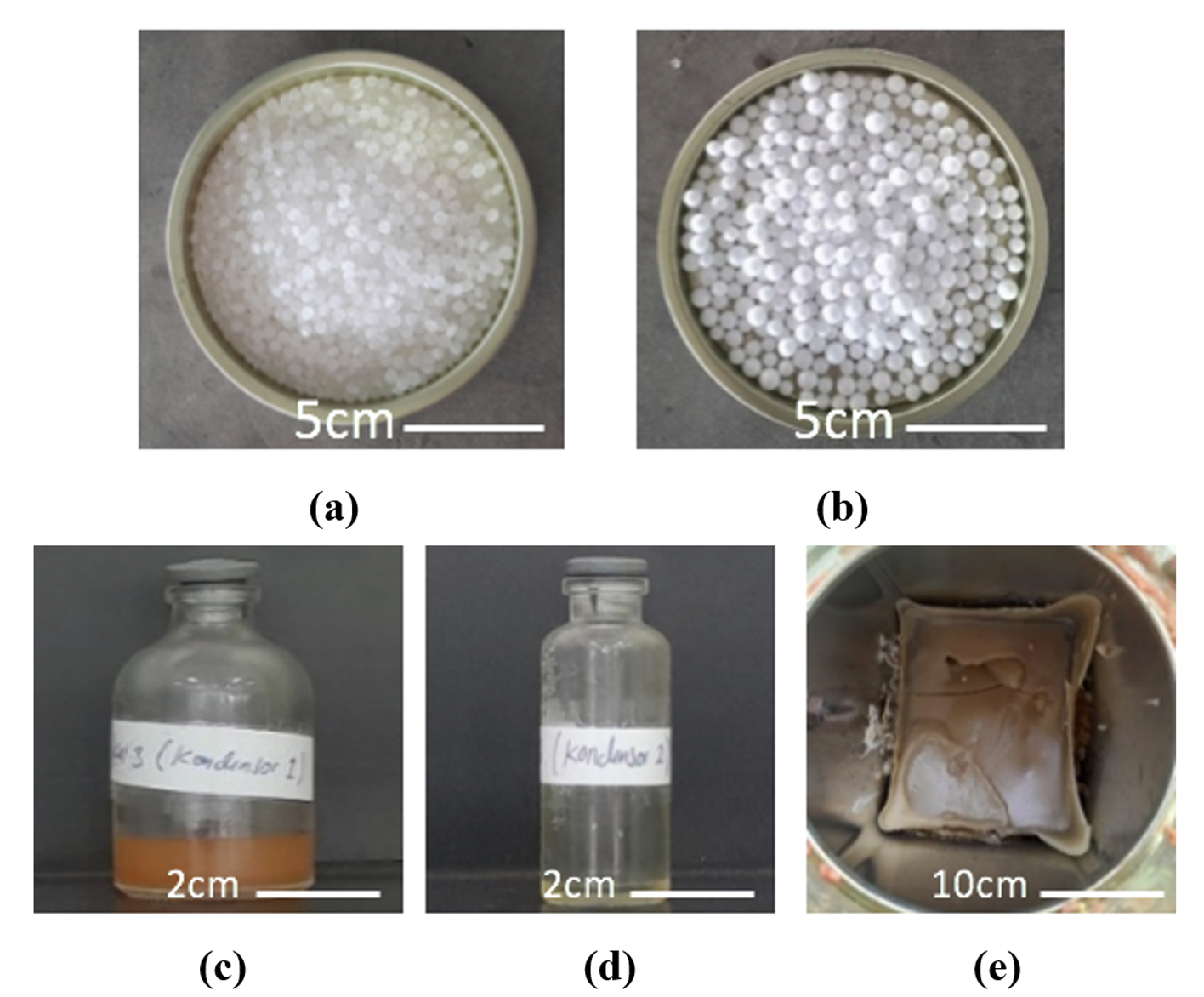

The purpose of this study was to determine the chemical compound content of polystyrene and linear low-density Density Polyethylene (LLDPE) microparticles after the pyrolysis process analyzed by Fourier Transform Infrared (FTIR). The pyrolysis was done by decomposing 307.6 g of a mixture of LLDPE particles (sizes of 5000 am) and polystyrene particles (sizes of 3000 µm) with a ratio of 1:1 for 180 min at a temperature in the range of 120-190°C in the absence of air using a closed batch reactor (length x width x height = 14.4 x 17.3 x 24 cm). The reactor had outlets connected to condensers (cooled at 24°C). The condensers were set in series, with condenser 1 directly connected to the reactor and condenser 2 positioned at the outlet of condenser 1. The pyrolysis result in the first condenser was a brownish-yellow liquid (15 mL) with a strong odor. The second condenser produced a yellow liquid (2 mL) and a distinctive odor. After the pyrolysis, the reactor contained a brown solid (residue). Different chemical compositions were detected. The sample from condenser 1 contained C=C ethylene bonds, C=C styrene aromatics, and C-H long-chain alkanes, whereas the second condenser contained -OH bond (like water). Further, when the samples were compared with pure LLDPE and Polystyrene, there was no C=C bond. This pyrolysis process showed two reactions: the end chain cracking and random cracking. This study brings ideas in the pyrolysis of plastic wastes, supporting current issues in the sustainable development goals (SDGs).

© 2026 SciEnggJ

Philippine-American Academy of Science and Engineering