VOLUME 18 (Supplement)

SciEnggJ 18 (Supplement) 299-310

available online: 22 August 2025

DOI: https://doi.org/10.54645/202518SupVPE-57

*Corresponding author

Email Address: nandiyanto@upi.edu

Date received: 10 September 2024

Date revised: 11 November 2024

Date accepted: 30 December 2024

ARTICLE

Exploring biomass-based brake pads from various construction wastes in microparticle sizes: Advancing environmentally friendly solutions and student entrepreneurship for sustainable development goals (SDGs)

2Universitas Pendidikan Indonesia, Bandung, Indonesia

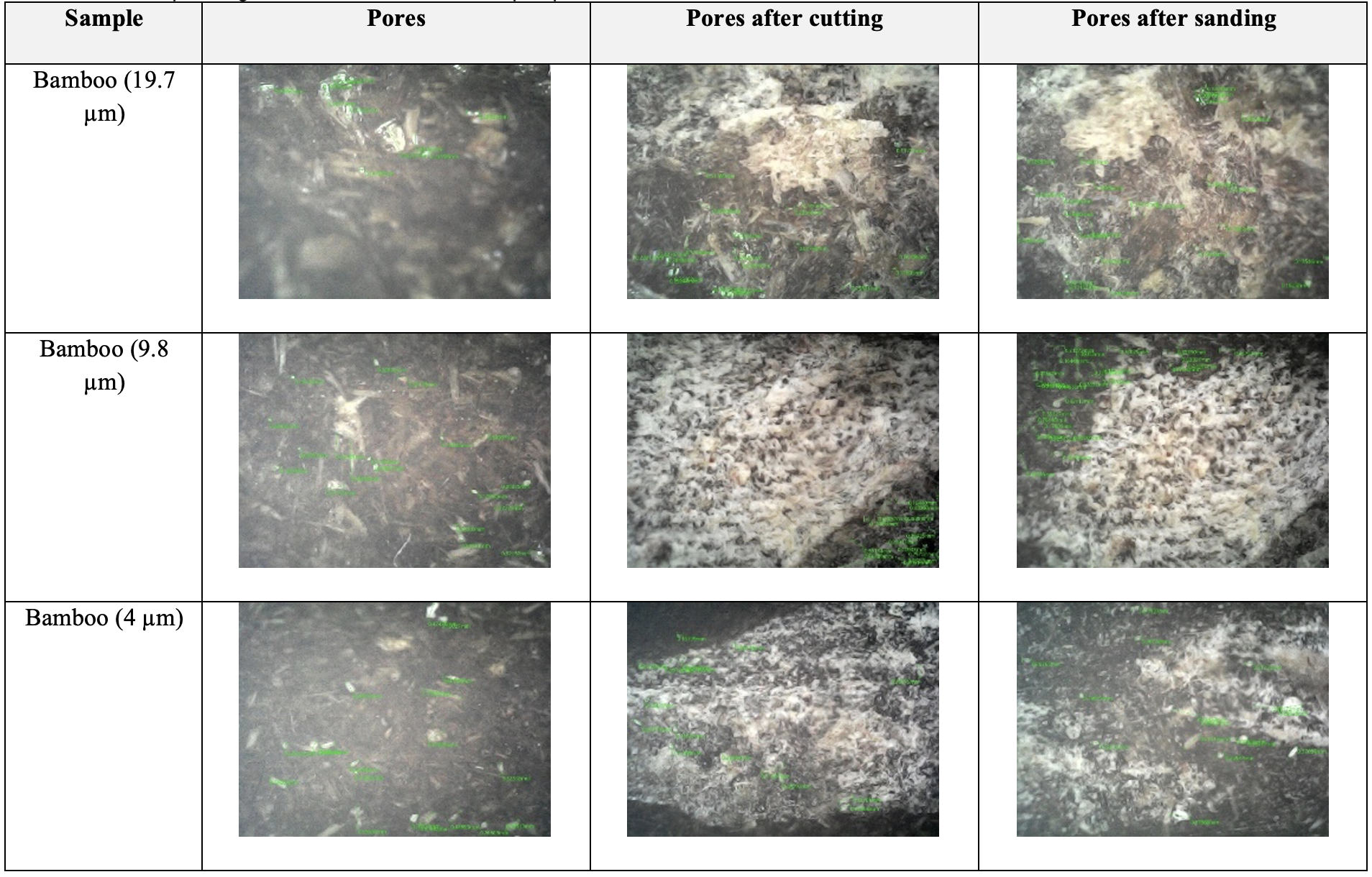

This study analyzed the effectiveness of brake pads made from biomass materials, from building construction waste, which was done to find alternative brake pads that are environmentally friendly. This article also examineds the development of entrepreneurship to support sustainable development goals (SDGs). The methods included experiments, verification, and descriptive analysis. We utilized Borneo sawdust, mahogany, and bamboo as biomass materials for making brake pads. The results indicated the prospective construction waste materials as raw materials for brake pad production, assisting the SDGs by providing ecologically friendly solutions and lowering the amount of trash generated during construction. Mahogany wood dust biomass with sizes of 4 µm was the most effective material composition to be used as an environmentally friendly brake pad, compared to Borneo wood dust and bamboo. Mahogany had greater durability and friction qualities. The results also showed the importance of this study for government, business, and academic institutions to work together to foster student entrepreneurship and the growth of sustainable innovation, helping achieve the SDGs.

Further, when the samples were compared with pure LLDPE and Polystyrene, there was no C=C bond. This pyrolysis process showed two might reactions: the end chain cracking and random cracking. This study brings ideas in the pyrolysis of plastic wastes, supporting current issues in the sustainable development goals (SDGs).

© 2026 SciEnggJ

Philippine-American Academy of Science and Engineering